|

Low-voltage servomotors in automated guided vehicles Automated guided vehicles are increasingly being used in intralogistics to digitalize, automate and streamline various processes. Battery-powered vehicles require energy-efficient drives for compact installation spaces that meet high demands in terms of power density and dynamics. Groschopp pushes the limits of what is physically possible when designing low-voltage servomotors in order to realize optimal drive solutions for a wide range of applications. |

|

Groschopp News & Press

Compact, efficient and powerful servomotors

|

Automated guided vehicles (AGVs) are used in automated guided vehicle systems (AGVs). They are controlled via intelligent network technologies and are able to transport goods or materials without human interaction within production, storage or logistics processes. In intralogistics, increasing efficiency is the top priority when using battery-powered transport vehicles. |

|

As the installation space of the vehicles is generally limited, but high dynamics and power density are required, this poses particular challenges for the design of the low-voltage servomotors. Battery operation also means that energy efficiency plays a major role, because the further a transport robot can travel in a warehouse, for example, without charging interruptions, the better. Safety brakes must also be available so that the automated guided vehicles can stop reliably if there are obstacles or people on the route.

Decades of experience in the low voltage range

Groschopp has been developing and producing compact and robust servo motors for the extra-low voltage range from 24 V to a maximum of 60 V for more than 30 years, making it one of the pioneers in this field. We have already been working with safety extra-low voltage in our servo motors for the pharmaceutical and food industries. "This means that we now have a wealth of experience when it comes to energy-efficient servo motors in the low-voltage range. The company uses this expertise to develop solutions for a wide range of industries and, among other things, to meet the high demands placed on drives in automated guided vehicles.

|

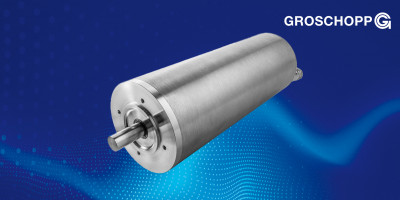

Despite their compact size and high energy efficiency, the manufacturer's EGK servomotors for the low-voltage range are particularly powerful and dynamic. Basically, these are contradictory design objectives. In order to fulfill them, we pursue a very high standard and always go to the limits of what is physically possible when developing our drive solutions. |

|

|

Modular product kitWith the EGK series, drive specialist Groschopp offers a comprehensive, modular product kit with servomotors in various sizes with and without controllers and with different gearbox types, which can be tailored precisely to the requirements of the respective application. |

|

Our low-voltage servomotors are ideal for use in battery-powered transport robots. We are constantly investing in the further development of our products so that we are always at the cutting edge of technology. The basis for the success of the company's drive solutions is its in-house development department. It has state-of-the-art tools, a specially equipped prototyping department and its own laboratory. To create new products or customer-specific concepts, a team of highly qualified employees work together across disciplines: from development and design to production, product management and sales. Groschopp is also involved in joint projects with universities and partner companies in order to drive forward the development of innovative and economical drives in the field of electromobility and AGVs and to keep up to date with the latest research.

|

One example of this is a research project by students at the Technical University of Novi Sad in Serbia, who have developed an autonomous robot that can recognize and automatically remove waste. The intelligent waste collection robot is driven by the electronically commutated EGK 48-60 low-voltage servomotors from Groschopp together with a worm gearbox and integrated servo controller. |

|

This enables smooth movement and precise positioning. In addition, the drive solution can be adapted to any application thanks to the freely programmable software and the numerous electronic and design options. The student association Mi (µ) Robotics even won the Eurobot Competition 2022 with this compact, flexibly configurable and powerful solution.

Drive technology according to customer requirements

Groschopp manufactures motors in small and medium quantities, but also in large series. The specialists from Viersen also realize unusual designs or use special materials as part of individual adaptations according to customer specifications.

|

Groschopp drive components are manufactured on state-of-the-art machines and automated production lines. A fully automated winding line is available for the electronically commutated motors and fully automated production lines for pole coils and armature winding are available for all other motors. This guarantees efficient and fast production as well as a high degree of flexibility for special requirements. |

|

We offer tailor-made solutions that - depending on the area of application - implement the maximum technically and economically feasible from the application. In addition, the motors are tailored precisely to the respective application in terms of speed and efficiency. Sustainability also plays an important role at Groschopp: the drives from the Viersen-based company are characterized by their high quality and are particularly low-wear, durable and therefore extremely sustainable, even under heavy loads.

Do you have any questions about our servo series or would you like to plan your application with our engineers? Then get in touch with us - we look forward to hearing from you!

Publikationen

13.12.2024

Compact, efficient and powerful servomotors

09.10.2024

PM DC motors in new sizes

11.09.2023

New generation stainless steel motors

08.08.2023

75 years Groschopp

15.12.2022

New two-stage spurwheel gearbox

04.03.2022

Ukraine war - How does Groschopp react and which impact does it have on the supply of our customers?

22.07.2019

IGLC-Motors – Better than standard motors

12.01.2016

Groschopp develops complete motor-housings